About Weldon Sp. z o.o.

Weldon Sp. z o.o. is a

company operating in construction and steel industries. Company’s registered office and main, modern production plant opened in 2010 are located

in south-eastern Poland, in the village of Brzezówka near Ropczyce. Besides, the Company operates in production department in Dębica where there

is company’s own steel constructions galvanisation plant. Both plants are located close to A4 motorway and railway line. The Company is also a

majority shareholder in AmTech company – a manufacturer of frame buildings based upon light steel frames. Currently, Weldon Sp. z o.o.

employs total number of more than 550 workers. Productive capacity in steel treatment is currently up to 400 tons monthly

and it is planned to be increased in the near future.

Company’s offer:

Main products of the Weldon company are containers

and modular buildings, steel structures and noise barriers. The Company also has its own galvanisation

plant.

| Acoustical barrier panels | Steel structures | Containers modular buildings |

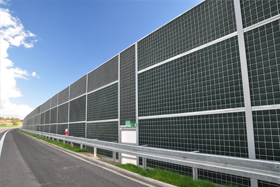

Acoustical barriers, sound barriers, Green Wall, glass sound barriers

Acoustical barrier panels produced by Weldon Sp. z o.o. are used to construct the noise barriers near roads

and motorways, which reduce the roadway noise to the level required by standards. Such barriers are constructed the most frequently together with

newly built roads and motorways and also near the existing traffic routes when they are repaired or modernized. Due to very good acoustic parameters:

sound insulation and absorption, they may also be used to make the acoustical barriers i.e. in form of fencing around

factories and industrial facilities which emit noise of the level exceeding allowable standards. The panels may also be used for realization

of various acoustic enclosures or structures for acoustic isolation of machines or devices which emit noise.

The manufactured acoustical

barrier panels have technical approval from Road and Bridge Research Institute, no. AT/2012-02-2861 and AT/2011-02-2743/1 and CE certificate

which approves them for use within the entire European Union area. Apart from Green Wall noise barriers, in our offer we have also sound barriers

made of acrylic glass, which are installed in locations where transparency of noise barrier is required. Green Wall acoustical barrier panel consists

of corrosion-proof, galvanized frame together with steel mesh protecting the panel surface from outside and the filling which isolates and absorbs

the sonic waves. Panel surface is covered with green plastic mesh which ensures the external appearance and protects the filling of sound barrier.

Green Wall acoustical barrier panels are produced with several standard dimensions adapted to supporting structures and with several standard

thicknesses. Apart from noise barriers we also offer other elements of road infrastructure – supporting posts for noise barriers, gates,

passageways and connectors.

Steel structures, hall and warehouse structures, production halls, warehouse halls, modular halls

The Company has modern machinery fitted for production of steel structures as well as experienced, qualified welders. We have,

among others, modern welding robot and two multi-function automated drilling and cutting units for steel structures, together

with shot blasting machines. Welding stations offer the possibility to make the plate girders. Our own steel structures

paintshop and galvanisation plant which enables galvanisation of elements with maximum dimensions 6500x1400x2400mm and the weight of

up to 3 tons complete the list. Galvanisation plant capacity is up to 100 tons of steel structures daily. The Company holds a Qualification Certificate

no. 224/1074/IV/2012 of The Institute of Welding in Gliwice, which allows us to perform production and welding jobs for making, assembly and overhauls

of class 1, 2 and 3 steel structures as per PN-M-69008 standard and steel building structures according to the requirements of PN-B-06200 standard.

We also have the Quality Certificate according to EN ISO 3834-2 and our employees hold International Welding Engineer

diplomas.

We offer production of welded steel structures galvanised and/or coated according to customers’ orders, delivery to the site

and also the installation. We have all necessary equipment (transporters, cranes, lifts) for complete service of even huge Investments.

Modular hall structures constitute novelty in our offer – due to unification of particular parts of steel structures, we have

managed to decrease the costs of steel for production of a steel hall and shorten the time of realization of steel structure.

Office containers, living containers, social containers, construction containers and changing room containers, modular buildings, schools made of containers, kindergartens made of containers. Washroom containers, changing rooms and washrooms in containers, portable toilets, sanitary units. Technical containers, specialist containers, warehouse containers, sea containers.

Currently, the base offer of the Company includes over a dozen of container types: construction, social and

office, sanitary, living, caretaker’s lodges and porter’s boxes. All containers may also have individually made configurations of walls, windows,

doors, stairs and other elements of equipment. In the record year 2008, we produced more than 3000 containers, which makes us be one of the largest

manufacturers of containers in our region of the Europe. We have great experience in realization of container modular buildings

– so far our installation teams have realized several tens of such investments in Poland and in European Union. Those investments include also

schools and kindergartens made of containers and office backups for large companies.

Office containers

produced by Weldon Sp. z o. o. are most often used by construction workers and companies as back-up facilities at construction and investment

sites far from the place of companies’ normal operation. In office containers, there are organized the back-up facilities and

offices for the construction sites, workers’ changing rooms and once the containers are equipped with beds and furniture, they serve as bedrooms

for construction workers. Such equipped containers are called living containers. The most frequently they are joint together

into the larger buildings with sanitary containers (toilets, washrooms and showers).

Office containers offer space that

can be used for virtually any purpose. A single container has more than 13 sq.m. of floor surface and a capacity of 32 cu.m. The complete equipment

inside all the containers, which include windows, doors, electrical installation, heating installation, allows their immediate use after placement,

or after the connection of electricity. Containers may be placed together and joint into larger buildings – to get more space, the neighbouring

containers are made without connecting walls and the joints of the containers are insulated with mineral wool and masked with steel sheet works.

This way the modular buildings are made, which can be successfully used as offices for manufacturing, trading, service, design

and other companies, temporarily or permanently, and they can even be used as schools and kindergartens. Container buildings created that way

may be, if necessary, deinstalled and moved to other location or their space may be extended or decreased. Incredibly short time of putting them

into full operation is very significant feature of container modular buildings.

Due to their solid construction and modular, repeatable

dimensions, containers are very often used as housing or rooms for various machines, devices and even for entire control rooms. They are installed

as a part of existing infrastructure or added, if necessary, to present or even to already operating installations. Containers also enable installation

of the equipment at manufacturer’s site, start-up and adjustment and then transportation to target use location, quick connection and start of

the operation. Those containers are called technical containers. They are usually made according to a detailed order and generally,

only outside dimensions are standard. Those containers are frequently equipped with various additional elements related to the installed equipment:

broad service door, additional technical holes in walls, specially designed efficient electrical installations, etc.

Containers

and particularly modular buildings, depending on the needs, are frequently equipped with various additional devices: air conditioners,

kitchen appliances, various sanitary fittings: e.g. for disabled persons, internal or external stairs, platforms and landings, additional partition

walls, windows or even glazing of entire walls. We deliver the containers to the locations designated by customers, we offer the installation

and assure further servicing.

Dębica Galvanisation Plant

Weldon Sp. z o.o. has modern galvanisation plant in which steel structures and other steel elements are galvanized to protect

them against corrosion. Galvanising is the best, the most durable and relatively cheap method of dealing with steel corrosion. Galvanising is

often required as the only effective and long-lasting protection of steel elements, e.g. steel tanks or road barriers. Dębica Galvanisation Plant

is equipped with galvanizing baths enabling galvanisation of elements with maximum dimensions of 6500x1400x2400mm and the weight of up to 3 tons.

Productive capacity is up to 100 tons of structures daily.